Thanks to advanced sensor technology, no-code programming as well as state-of-the-art battery technology and higher energy density, autonomous mobile robotics is able to navigate autonomously, detect obstacles safely, evade these and create alternative routes. To ensure the continuous stable operation of our mobile robots, all KUKA vehicles are equipped with state-of-the-art Li-ion batteries, which are available around the clock in inductive charging mode. The result: 24/7 operation and 99% availability.

This unrestricted mobility opens up entirely new areas of application for robotics. It is used in a wide range of industries, including warehousing, manufacturing, healthcare and retail.

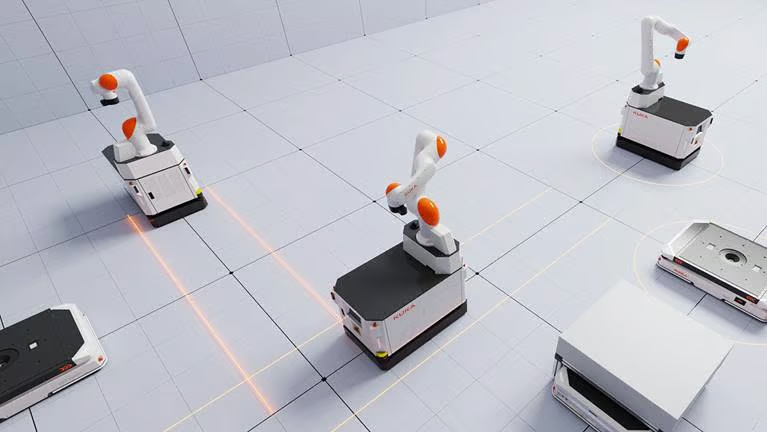

Our mobile transport platforms for all payloads are collision-free, operate in a swarm and offer absolute flexibility. And this both as a product carrier and a mobile production station.

Mobile manipulators are designed for safe transport of materials, machine tending, inspection, order picking and pick & place tasks. AMRs are capable of human-robot collaboration.

The navigation system enables intelligent control, real-time monitoring and optimization of the traffic flow of a heterogeneous group of vehicles (AGVs/AMR) in any configuration.

Our autonomous robots are developed and manufactured with the latest technologies and innovative functions to meet the highest standards in performance, reliability and safety. Our automation portfolio includes series products for industry that meet different specific requirements. These high quality standards are also applied exactly to the AMRs. Thanks to our extensive experience and specialized know-how, we are also able to develop targeted concepts for your tasks in this field.

Evaluation of the practical feasibility of a project through a thorough analysis of the following factors: technical feasibility, resource requirements, legal aspects and economic profitability.

Our global network of certified system partners is spread out around the world and offers in-depth expertise in the field of autonomous mobile robotics. Together, we offer reliable support for every automation task.

Design, development and execution of test setups in order to identify potential weaknesses or potential for improvement.

Our service: from the planning and selection of suitable mobile robotic solutions through to the simulation and smooth start-up along with efficient operation in warehouses or in production and onto the overhauling and modernization of the entire fleet system.